A IPU Group é uma empresa líder sediada no Reino Unido, que tem fornecido soluções de energia inovadoras há mais de seis décadas. Com uma presença global em diversos setores industriais, a IPU Group conquistou uma reputação pelo seu compromisso com a excelência no design e fabricação de sistemas de energia confiáveis e eficientes.

Produtos

Partners

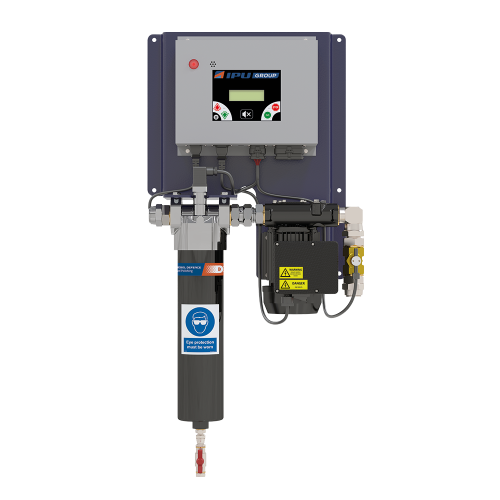

Especializada em soluções de partida de motores e polimento de combustível, a IPU Group oferece uma ampla gama de produtos e serviços projetados para garantir a continuidade operacional e a eficiência dos equipamentos em diversas aplicações industriais. No campo das partidas de motores, a empresa desenvolve sistemas avançados que garantem uma partida confiável em motores a diesel, mesmo nas condições mais exigentes. Por outro lado, suas soluções de polimento de combustível empregam tecnologias inovadoras para manter a qualidade e a limpeza do combustível, garantindo um desempenho ótimo do motor e prolongando a vida útil dos equipamentos. Com um foco na qualidade, confiabilidade e inovação, a IPU Group continua sendo uma referência no mercado global de soluções de energia.