A poultry farm implemented a hybrid energy system that significantly reduced diesel consumption during grid outages, without compromising animal welfare or production continuity. In this article, we detail everything about this success story.

Achievement: 65% reduction in diesel consumption with Servintel’s hybrid system

Together with Colomby and Servintel, a poultry farm dedicated to intensive production in Brazil’s Central-West region implemented a hybrid system that achieved a 65% reduction in diesel consumption during grid outages. This success story represents a concrete step toward energy efficiency and sustainability in the agro-industrial sector, without compromising animal welfare or production continuity. The hybrid system ensures a stable power supply and minimizes dependence on fossil fuels at the poultry farm.Challenge: Maintaining energy supply during critical intensive breeding cycles

The poultry farm’s production process is organized in 45-day cycles, where each shed houses chickens from hatching until they reach the ideal weight. During this period, energy demand is constant and growing:- In the first weeks, chicks require a stable heating system.

- As they grow, the need for forced ventilation and thermal control increases significantly, raising electricity consumption.

- At the end of the cycle, each shed goes through a two-week cleaning period, after which the process restarts.

Limitations of the traditional diesel generator model

Before the implementation of the hybrid system, the only solution was to rely on diesel generators. While they fulfilled their purpose, they presented several drawbacks:- High fuel costs

- Higher pollutant emissions

- Premature equipment wear due to intensive use

Implemented solution: intelligent hybrid system developed by Servintel

- Hybrid Control 1000: the brain of the system, prioritizing the use of grid, solar, and diesel energy under intelligent logic.

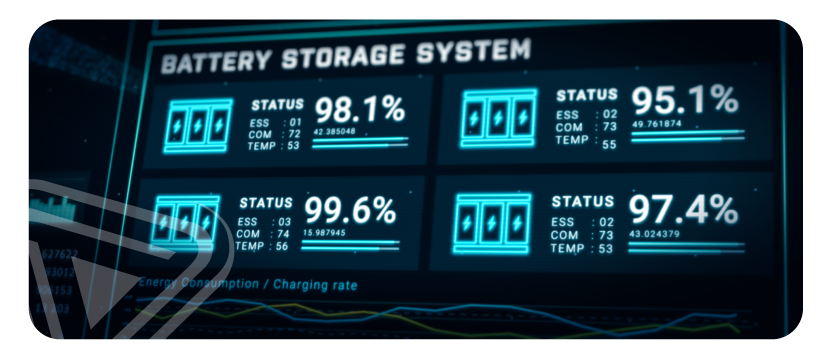

- Monitoring with WebSupervisor: real-time remote supervision to anticipate failures and analyze performance.

- Diesel generator with ComAp InteliLite controller: automatic and reliable backup in case of grid failure.

- Sungrow SG75CX-P2 inverters: solar energy integration, significantly reducing diesel use.

Results: production continuity, fuel savings, and sustainable operation

Thanks to the implementation of the hybrid system, the poultry farm achieved:- A 65% reduction in diesel consumption during grid outages.

- Continuity of the breeding process, even with an unstable power grid.

- Lower operating costs and reduced financial risks from interruptions.

- Reduced CO₂ emissions, moving toward a more sustainable operation.

- Real-time monitoring for data-driven decision-making.

Client testimonial: tangible impact on costs and sustainability

“Es un placer reafirmar nuestra alianza con Servintel, que ya lleva 23 años. Durante todo este tiempo, siempre confiamos en las soluciones que ofrece la empresa, adaptándose continuamente a las necesidades del mercado. The combination of sustainability with concrete economic benefits makes a big difference: solutions that significantly reduce carbon emissions while protecting profitability. For example, we managed to save approximately 1,500 liters of diesel per shed every 45 days with the hybrid system, which means fewer emissions and notable financial advantages. Solutions like this are exactly what Brazil and the world need to build a greener, more sustainable, and economically viable future. — Marcelo Colomby, Colomby EnergiaEnergy efficiency in poultry farms: what it is and how it’s measured

Energy efficiency is the ability to achieve the same (or better) results using less energy. In this success story, the poultry farm maintained stable production while drastically reducing fossil fuel use.How is energy efficiency measured?

- Comparing consumption before and after implementing the solution.

- Relating energy used to production output (e.g., kWh per production cycle).

- Calculating emission reductions resulting from lower diesel consumption.

Why is energy efficiency key?

- Ensures continuity of critical processes.

- Reduces operating costs and fuel dependency.

- Decreases carbon footprint, protecting the environment.

- Improves competitiveness in the agro-industrial sector.

Servintel as a strategic partner in the agricultural energy transition

In poultry farming, energy is not just another input: it can mean the difference between animal life or total production loss. The implementation of a hybrid system in this poultry farm in Brazil’s Central-West region demonstrates how technology can be a strategic ally to ensure reliability, energy efficiency, and sustainability.Transform the energy efficiency of your poultry farm with Servintel

This success story shows that a Servintel hybrid system can reduce diesel consumption by 65% in poultry farms, ensuring operational continuity and sustainability. Does your operation face similar challenges with unstable grids? Discover how to improve your farm’s energy efficiency with intelligent hybrid solutions. Contact us now and learn more about our hybrid energy automation systems. We also invite you to read another of our success stories: Successful conversion from diesel engine to biogas, achieved together with PESA.Summary

How much can diesel consumption be reduced with a hybrid system?

The poultry farm achieved a 65% reduction in diesel consumption during grid outages, saving 1,500 liters per shed every 45 days.How does the hybrid system ensure operational continuity?

Servintel’s hybrid system prioritizes grid, solar, and diesel energy under intelligent management, ensuring a stable supply even with unstable grids.What are the benefits of a hybrid system?

It improves energy efficiency, reduces operating costs, decreases CO₂ emissions, and enables real-time monitoring for poultry farm operations.