Products

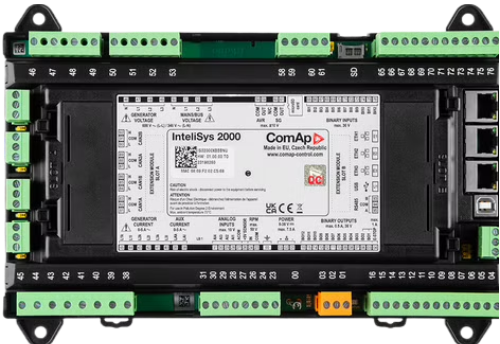

InteliSys 2000

General information

InteliSys 2000 sets an industry standard for advanced power generation control units. Tailored for various power generation applications, including gas gensets and cogeneration heat-power setups, it ensures cutting-edge performance with unrivalled PLC resources, modular expandability, and control algorithm flexibility. The InteliSys 2000 is developed in line with the latest market trends, grid code standards, and security protocols and comes with extensive communication capabilities.

BENEFITS

- Gas engines and CHPs applications support

- Multi-ECU support

- Integrated Modbus Master (Client) functionality

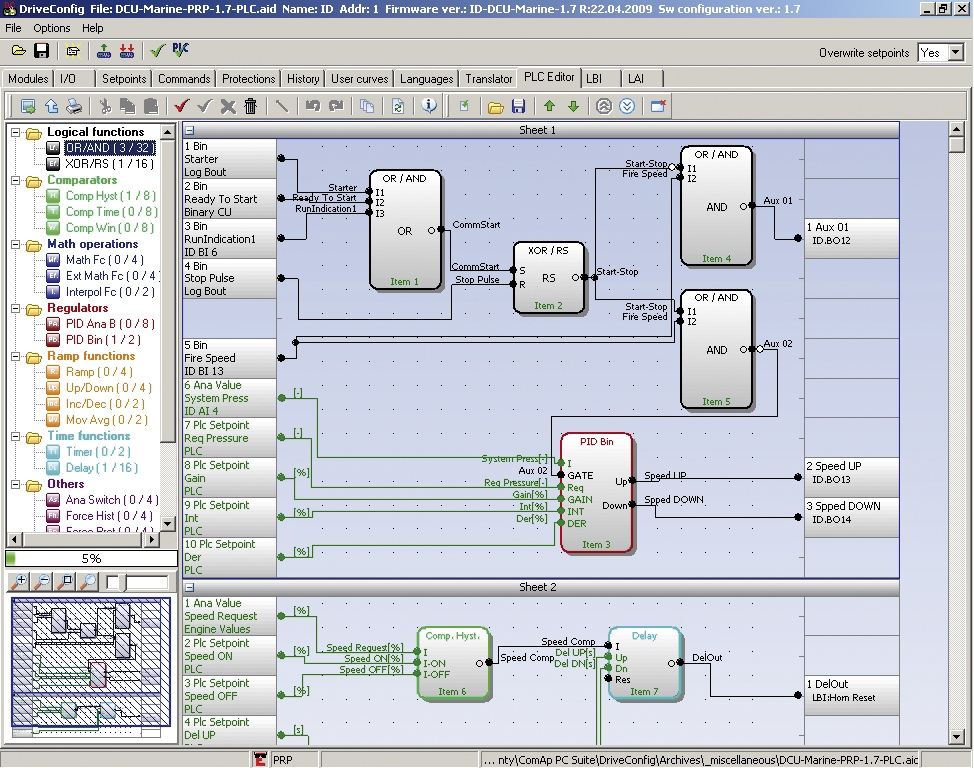

- Large and easy to use internal PLC editor

- 3 voltage sensing points

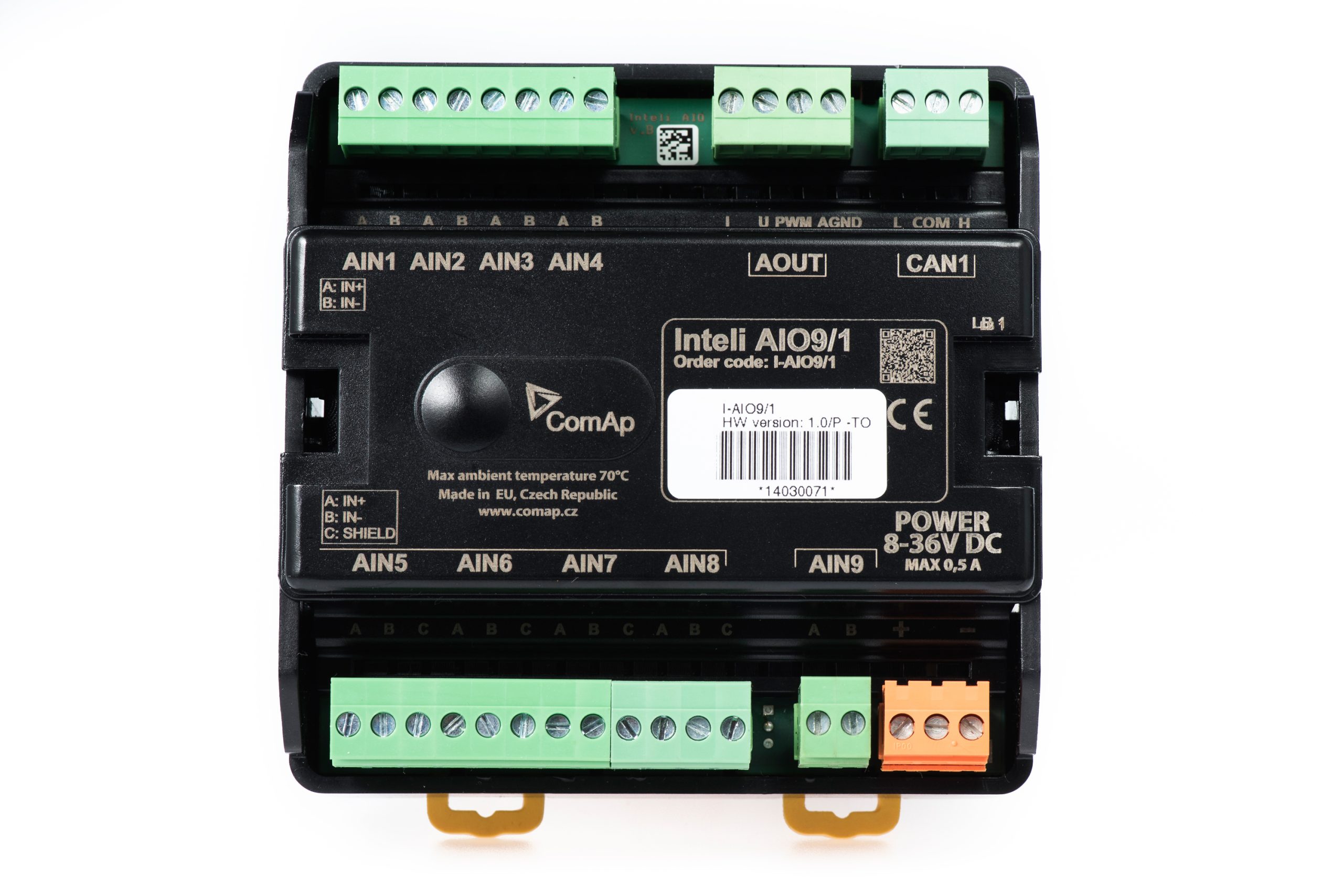

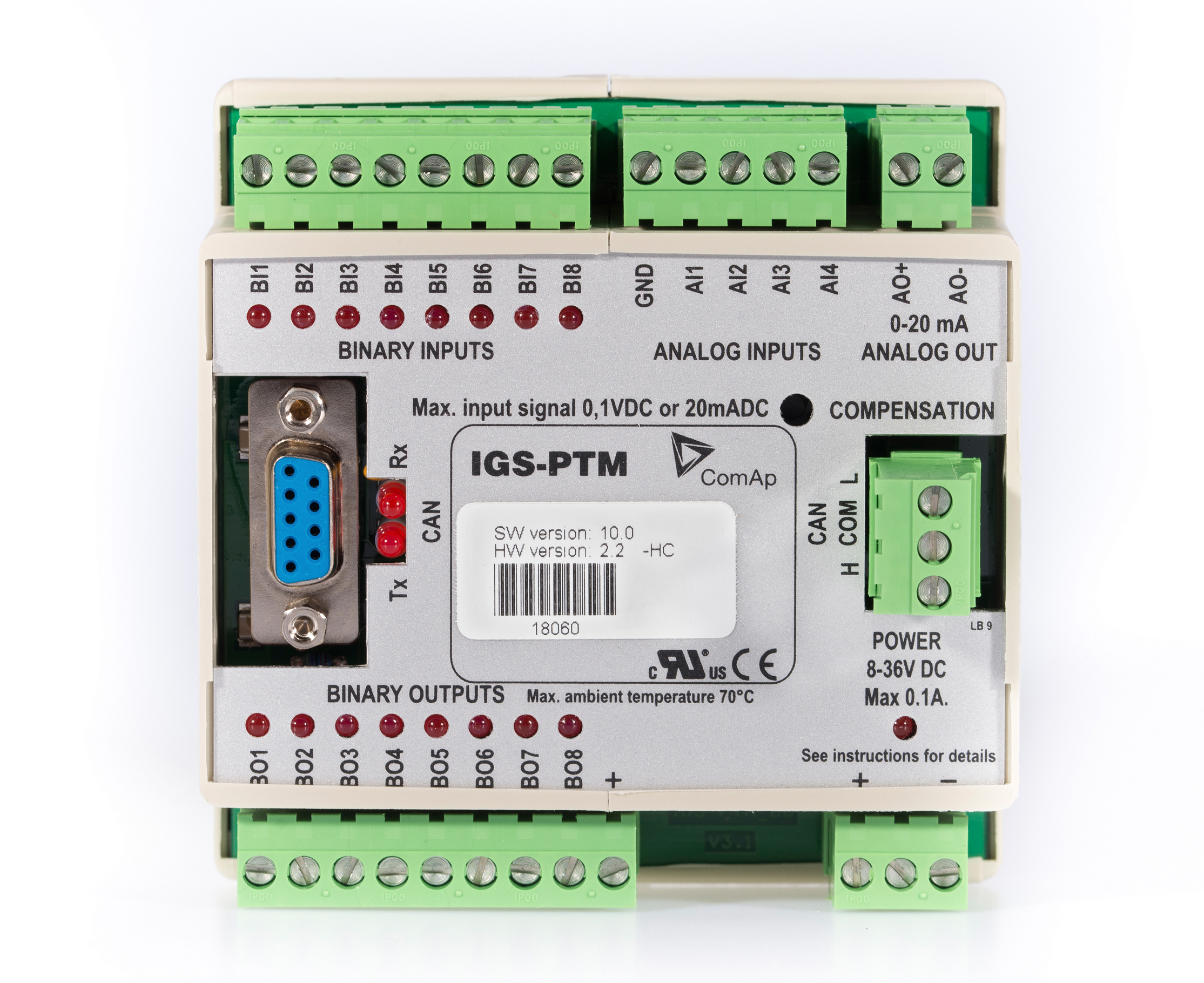

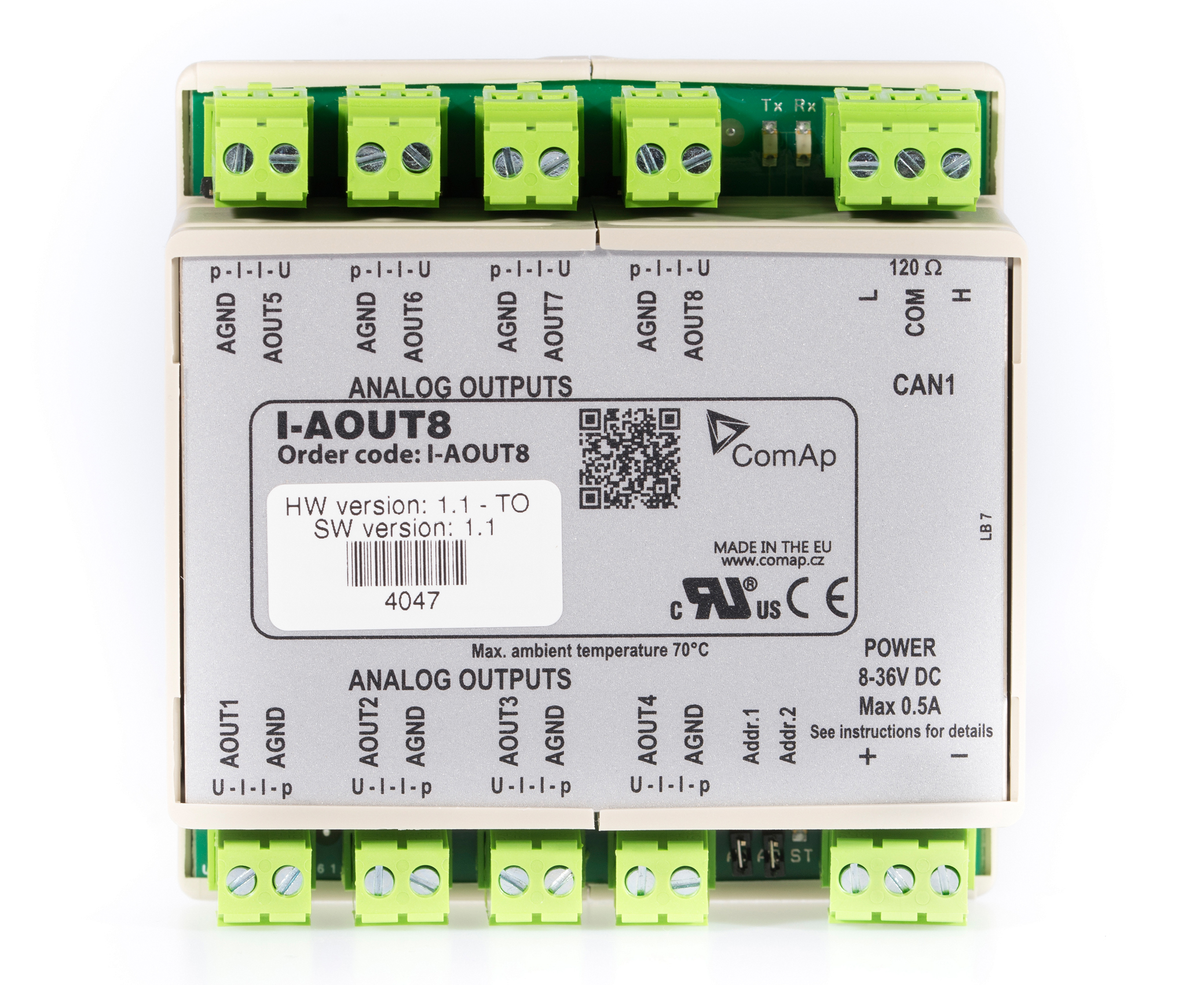

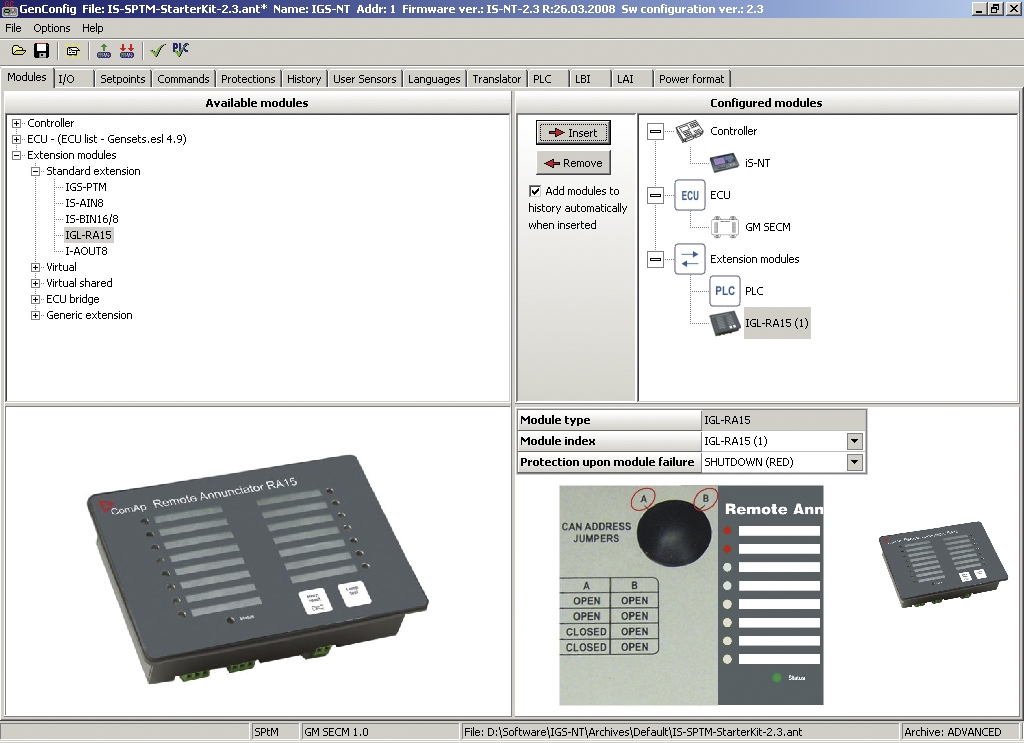

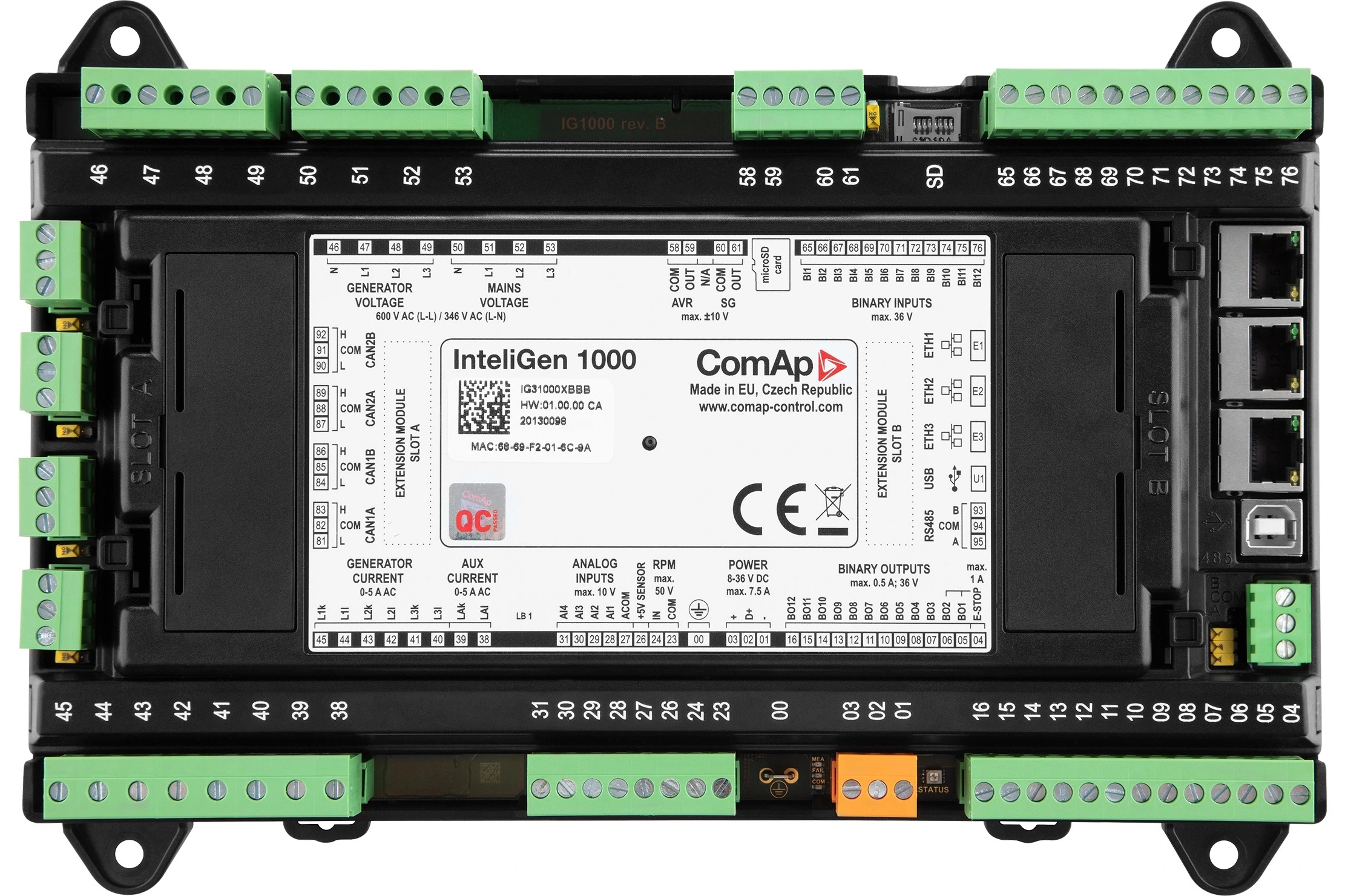

- Support of high number of I/Os CAN extension module

- Compliant to world-wide Grid codes requirements

- Lifetime history on micro-SD card

FEATURES

- Gas engine and CHP functions that provide easily configurable support

- Universal platform concept, which allows for the unit to be in various applications in addtion to gensets with gas/diesel engines

- 3rd voltage sensing point, enhancing the application’s flexibility and safety

- Hot-swap redundancy enabling a redundant unit to take over in case the primary controller fails, helping to minimise solution downtime

- New CAN FD inter-controller communication standard enabling cooperation with up to 64 additional gen-sets/mains/tie controllers

- Keeping your business and data as safe as possible, meeting the ISA 62443 level 2 – level 3 security requirements

- CAN bus redundancy ensuring that a redundant CAN line be created and take over in case of CAN failure

- Modbus Client which can initiate Modbus communication and control 3rd party devices

- Extensive built-in PLC interpreter with the use of ComAp’s free PLC Editor

- User setpoints groups to help organise user defined setpoints to logical groups

- Compatible load/VAr sharing and power management with other ComAp solutions

- Dynamic spinning reserve helping to deliver maximum amount of available energy from photovoltaics

- Multi ECU (Electronic Control Unit) enabling communication with more independent J1939 devices such as Engine Control Unit, AVR modules, Breaker, etc.

- Built-in CAN bus logger and event-based history for easy and fast troubleshooting

- User-defined protections and setpoints on top of default protection

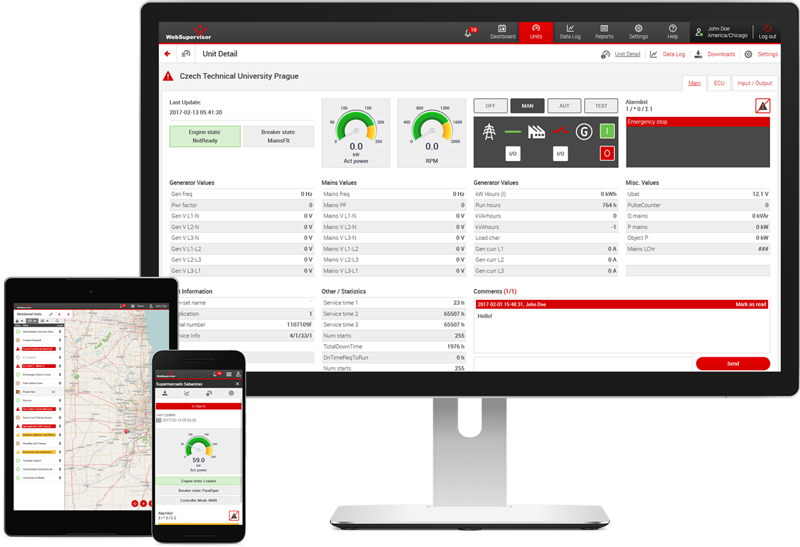

- AirGate 2.0 for easy connection to your equipment remotely, without worrying about your asset’s IP address

- More precise measuring with a True Root Mean Square measurement feature

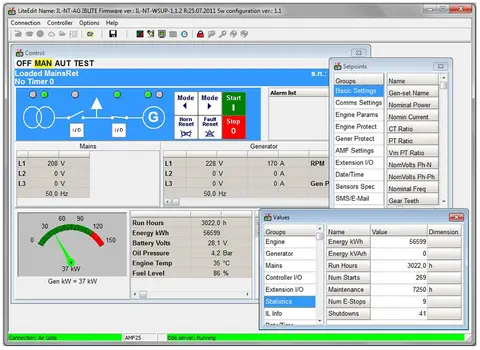

- Remote control and monitoring of your gen-set operations with WebSupervisor, our cloud-based fleet management tool

- Secure user management

- Droop regulation allowing load and Var sharing when the inter-controller’s communication is lost

- Peak shaving for limiting the import from the mains (e.g. due to higher prices)

- Load shedding ensuring the most important loads are running even when there is a lack of power

- Start-up synchronisation to minimise the paralleling start sequence time and get the gen-set system up and running with minimum possible delay

- Automatic Mains Failure that ensures automatic start of gen-sets and minimises downtime

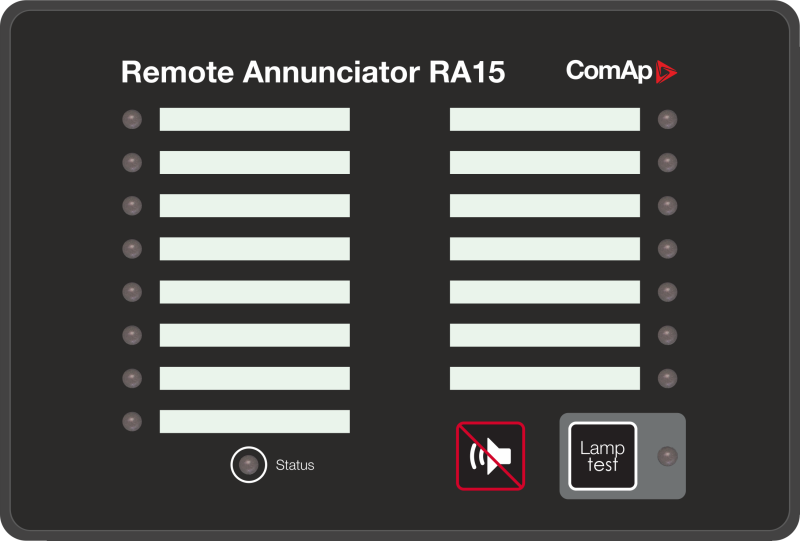

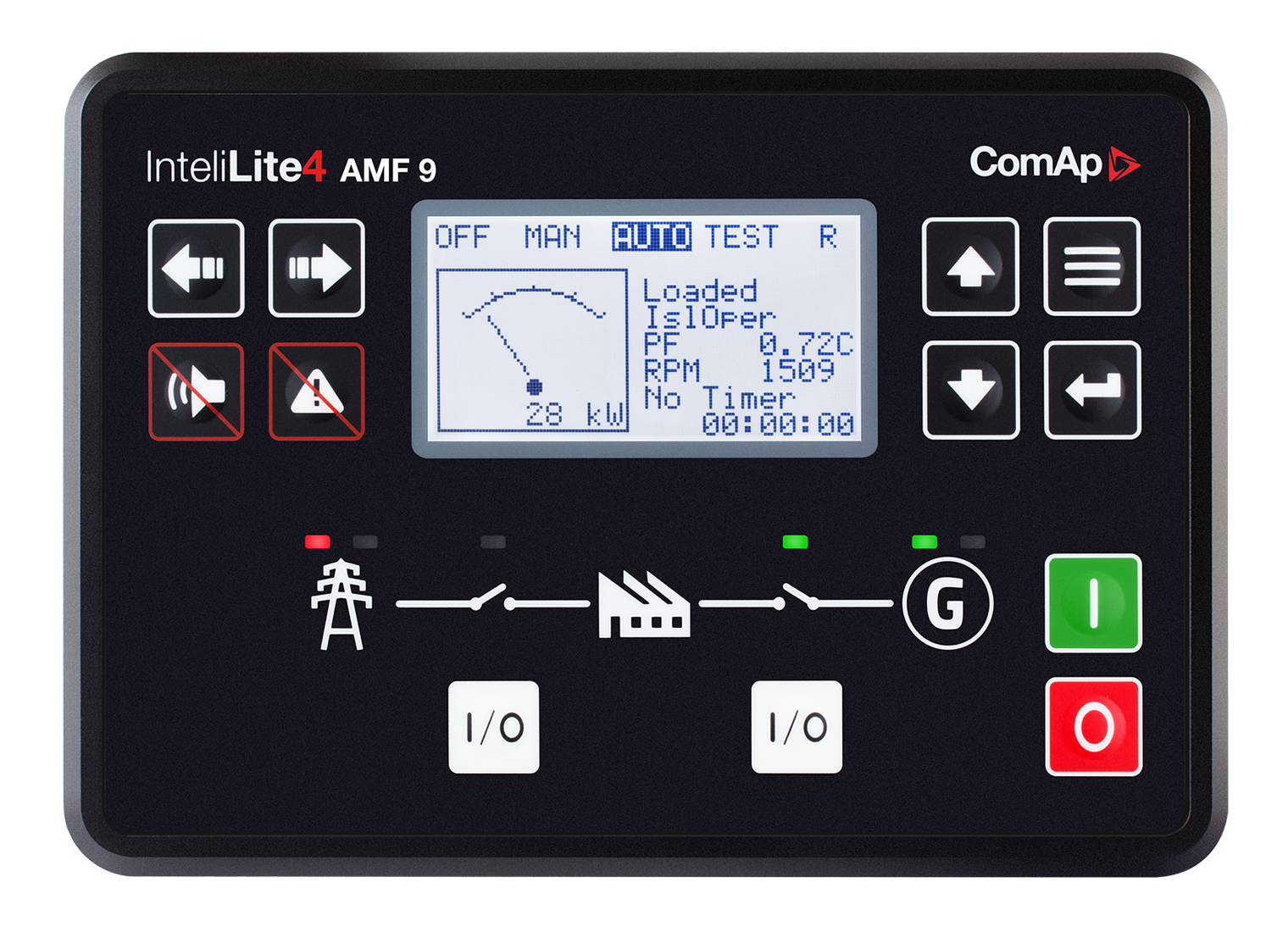

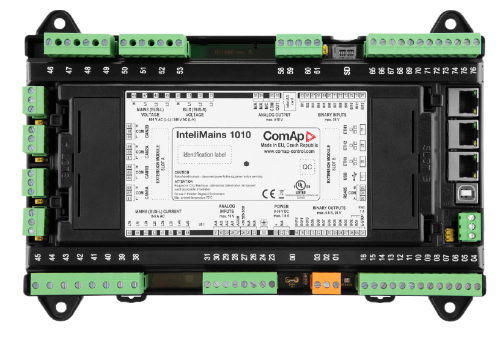

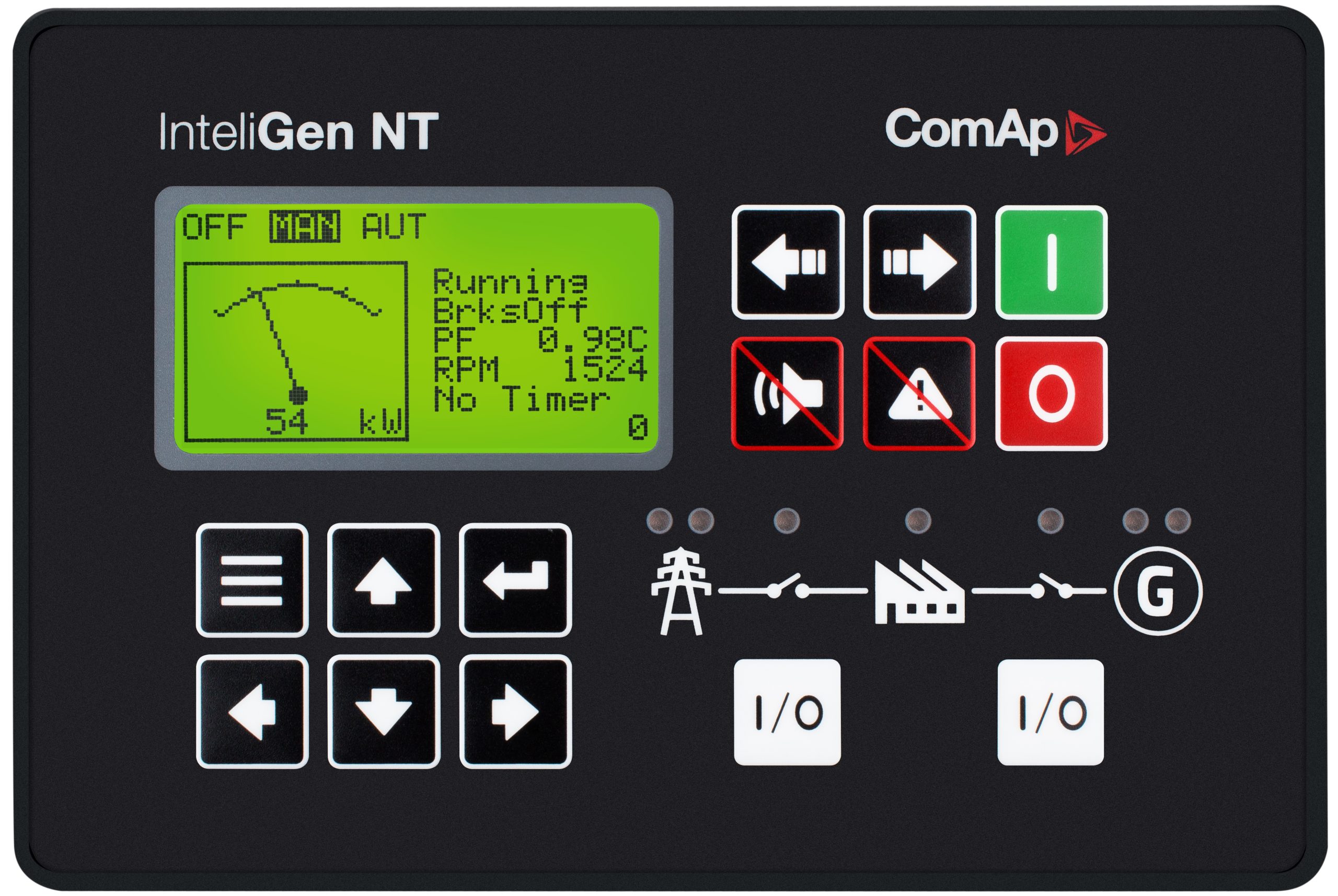

- A wide range of plug & play displays with automatically generated content that can be easily edited in our free Screen Editor

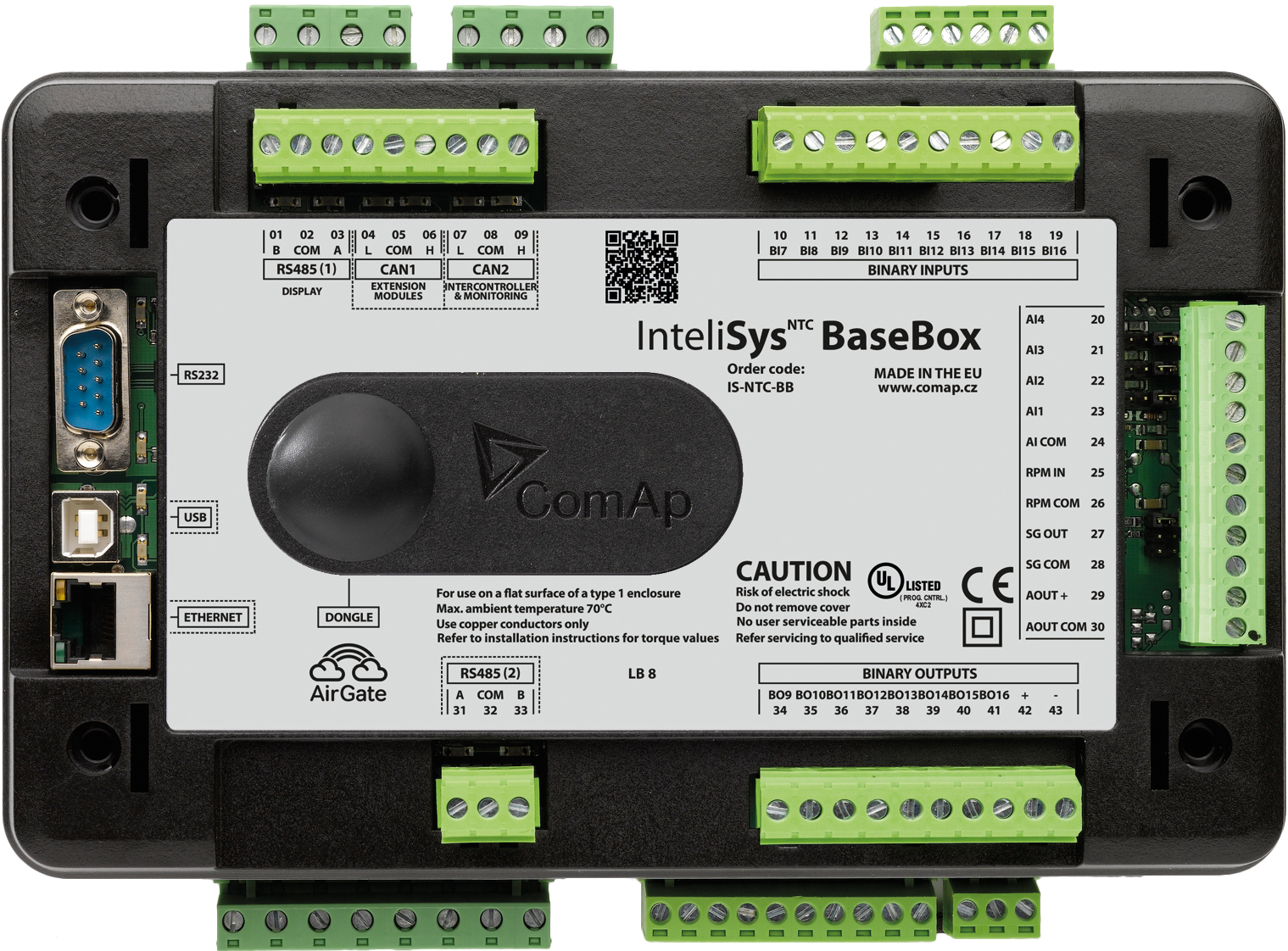

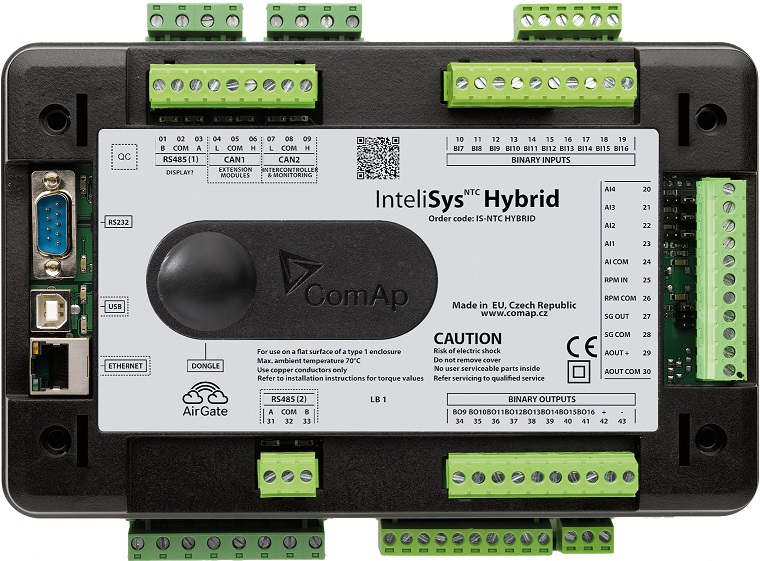

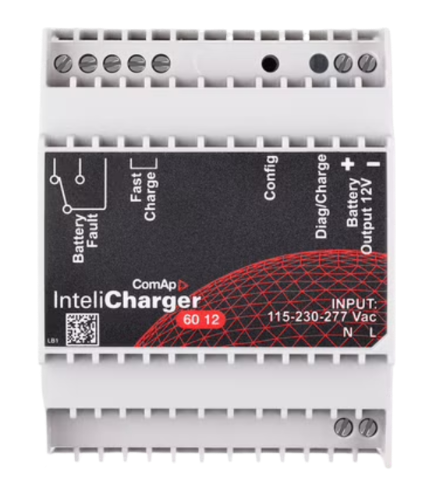

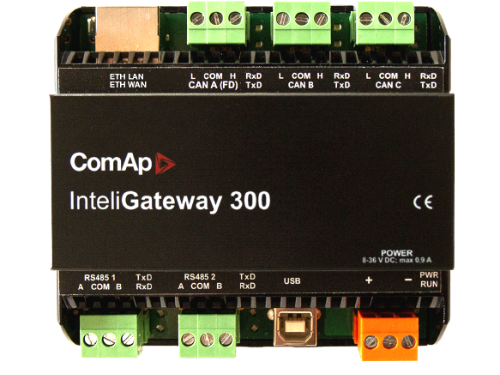

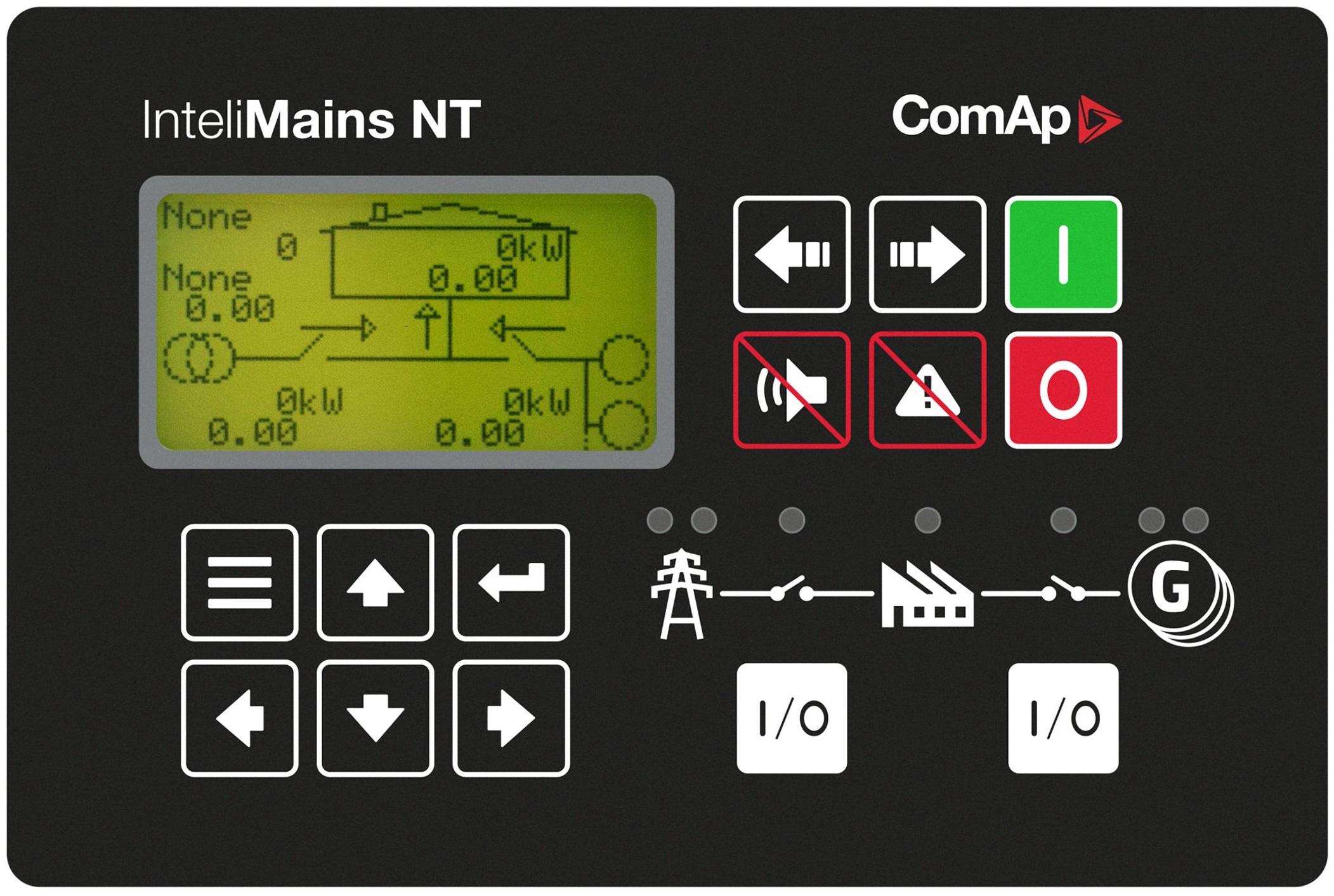

PRODUCTS

Other products