Products

InteliSys Gas

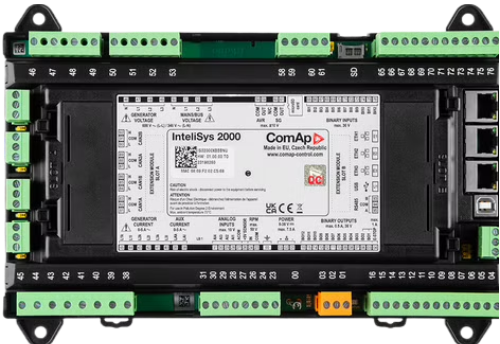

This equipment is in the process of being replaced. We recommend the following product InteliSys 2000.

General information

InteliSys Gas is designed to control, monitor, and protect the operation of any type of gas engine and/or CHP (combined heat and power) unit. The control unit boasts broad communication capabilities, numerous specialized predefined functions for gas/CHP/generators, and it offers complete pre-programmed control of the generating set, helping you save time with the configuration, commissioning, and management of your project.

BENEFITS

- Pre-programmed gas engine functionalities

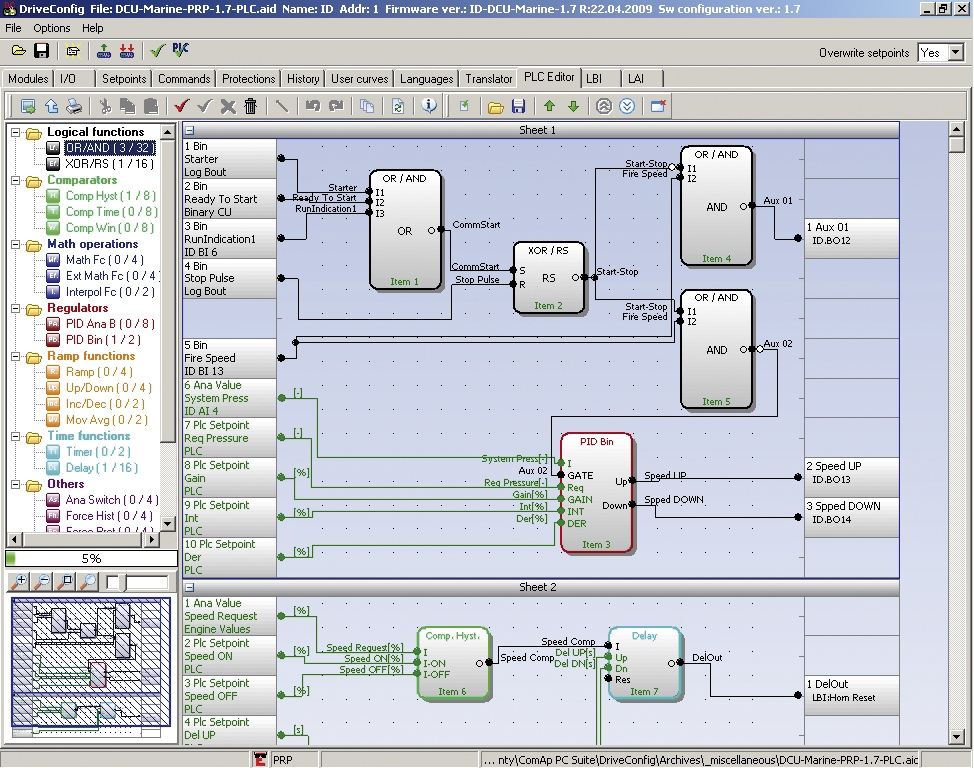

- Large built-in PLC interpreter

- CHP functionalities support

- Dynamic spinning reserve

- Gas engine management system

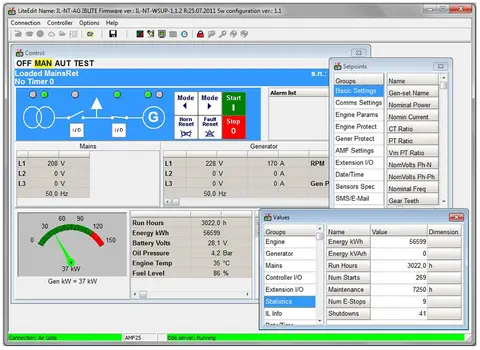

- Remote connection & monitoring

- User-defined protections and setpoints

- Pre-mortem history

FEATURES

- Pre-programmed functions typical for gas engines and generator-specific functions, enabling fast and easy configuration and commissioning

- Support for CHP functionalities through pre-programmed and ready-to-use functions such as derating, and power control by temperature request

- Built-in Air Fuel Ratio control algorithm for two gases or two independent mixers

- Centralized Gas engine management system helping you maximize the unit’s running time, simplify commissioning, and troubleshooting

- Event-based and history for fast and easy troubleshooting

- Dynamic spinning reserve helping to deliver the maximum amount of available energy from photovoltaics

- Support for complex installations with the option for cooperation with up to 32 additional gen-sets/mains/tie controllers

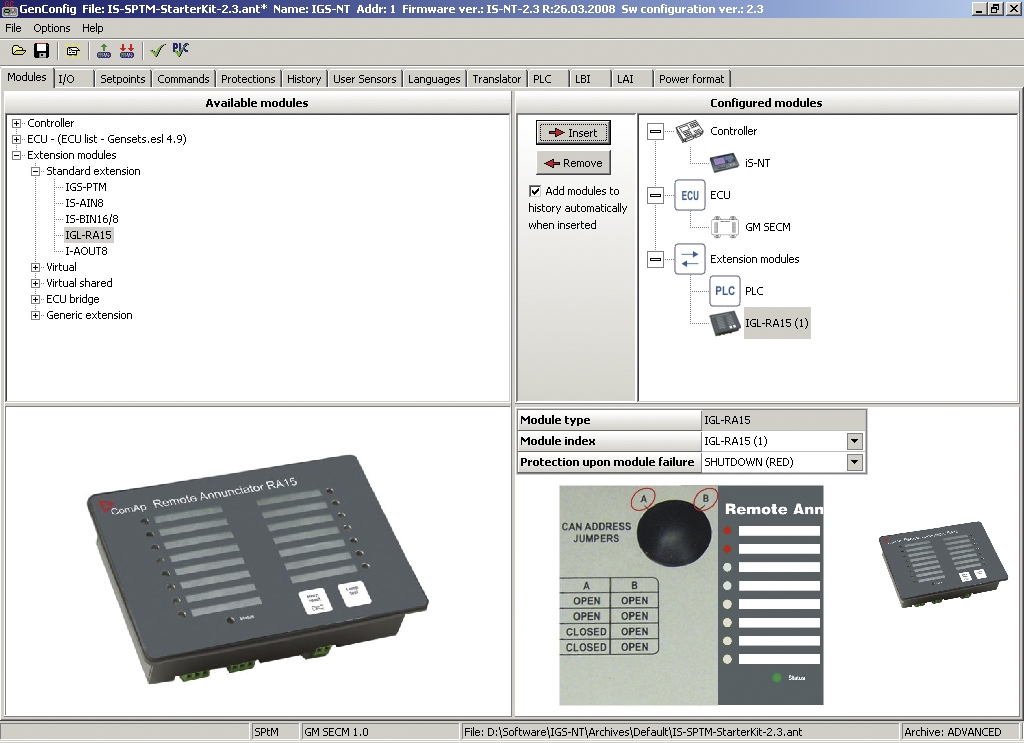

- Large built-in PLC interpreter

- User-defined protections and setpoints on top of default protection

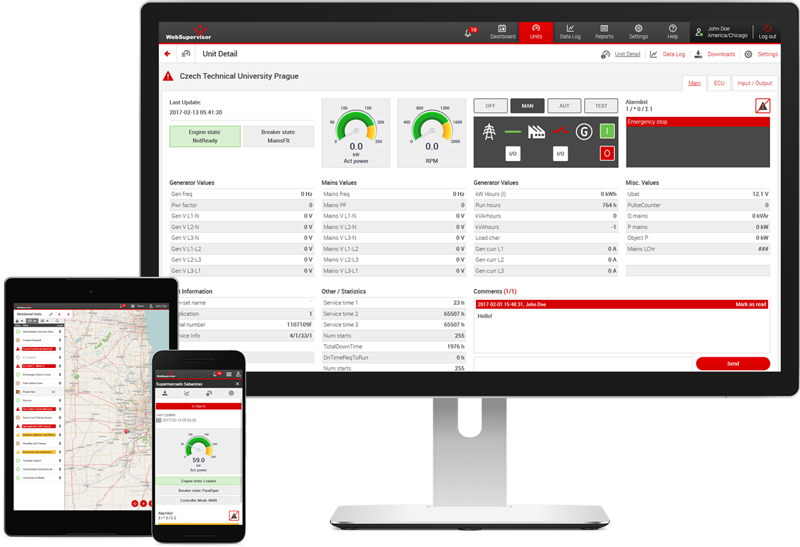

- Remote control and monitoring of your gen-set operations with WebSupervisor, our cloud-based fleet management tool, and AirGate

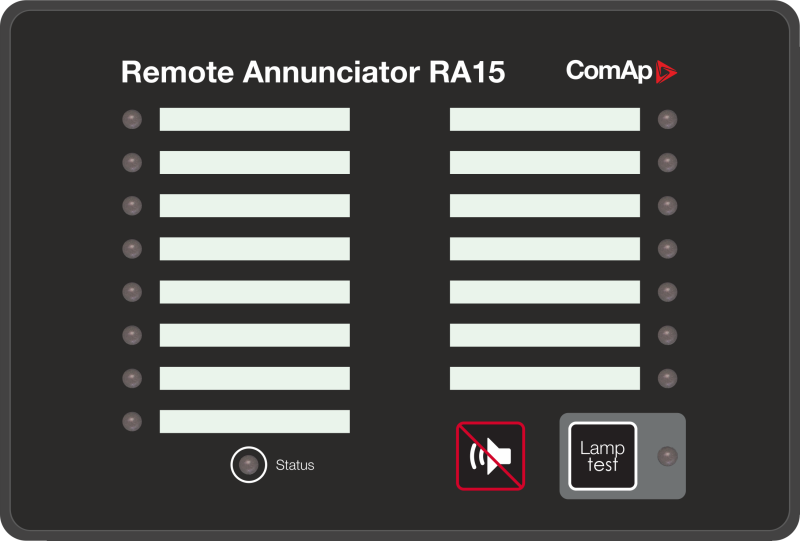

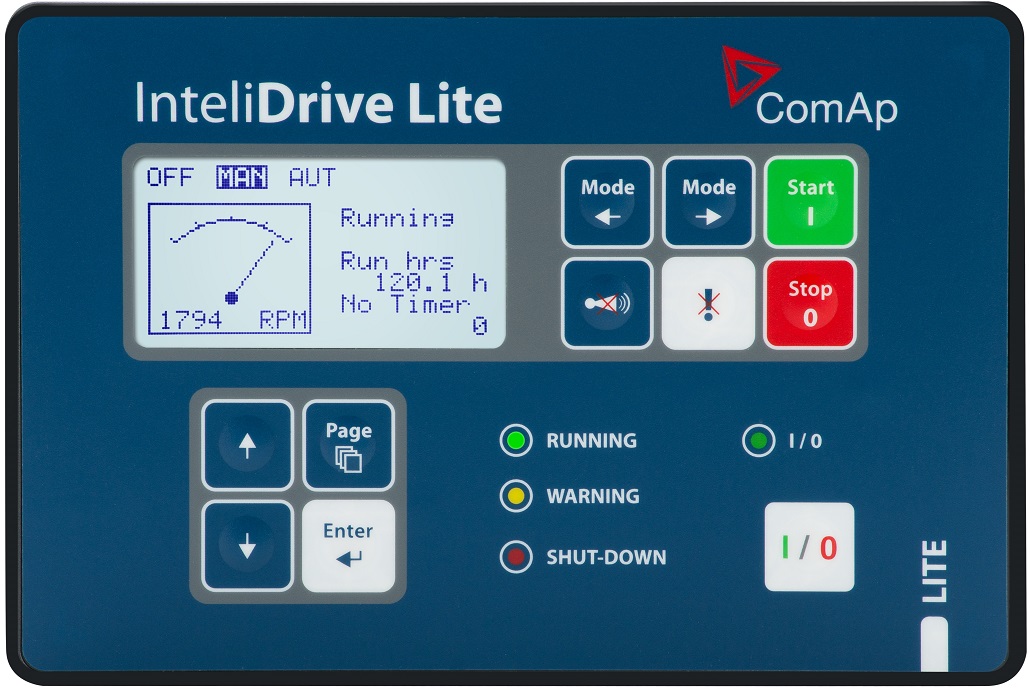

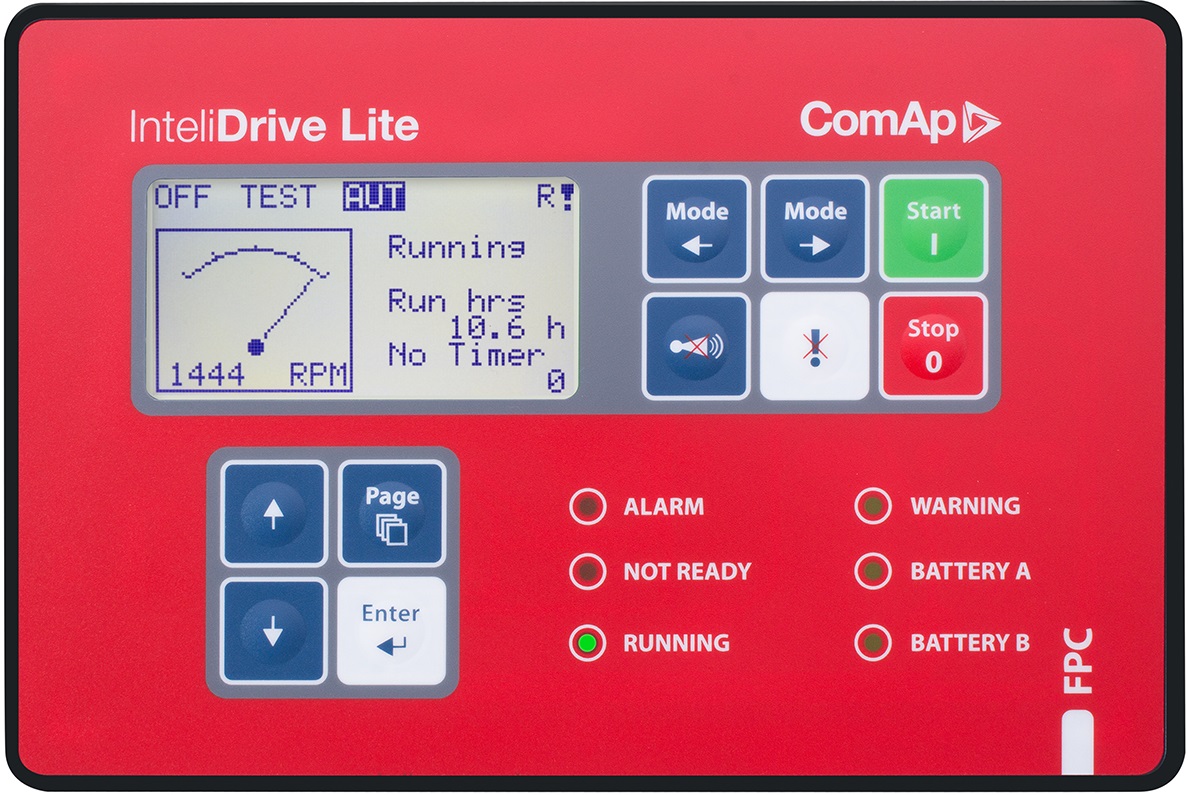

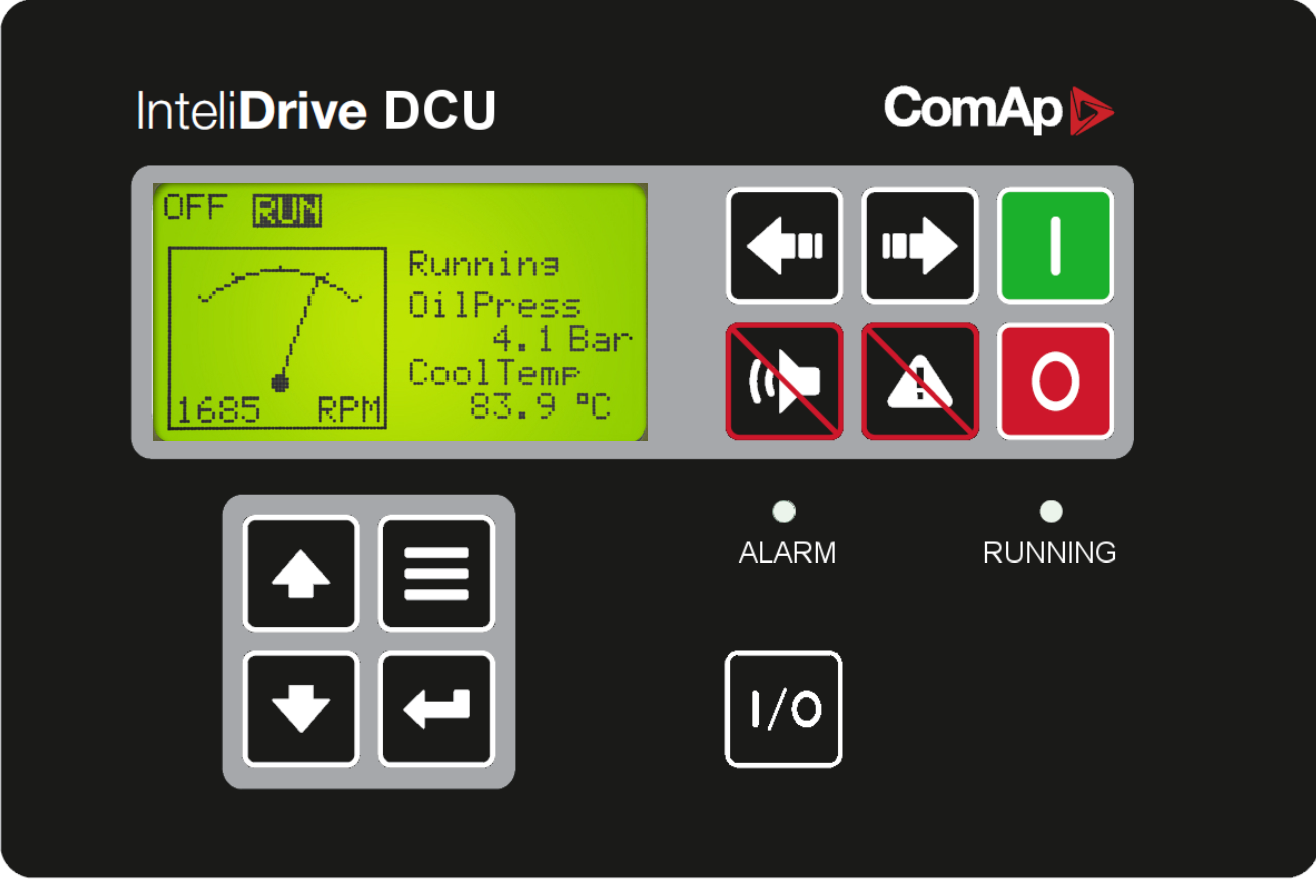

- A wide range of plug & play displays with free Screen Editor for designing top-level SCADAs

- More precise measuring with a True Root Mean Square measurement feature

- Built-in emergency stop mechanism for shutting off your machines in unexpected cases

- Compatible load/Var sharing and power management with other ComAp solutions, such as ComAp’s microgrid controllers

- Start-up synchronization to minimize the paralleling start sequence time and get the gen-set system up and running with the minimum possible delay

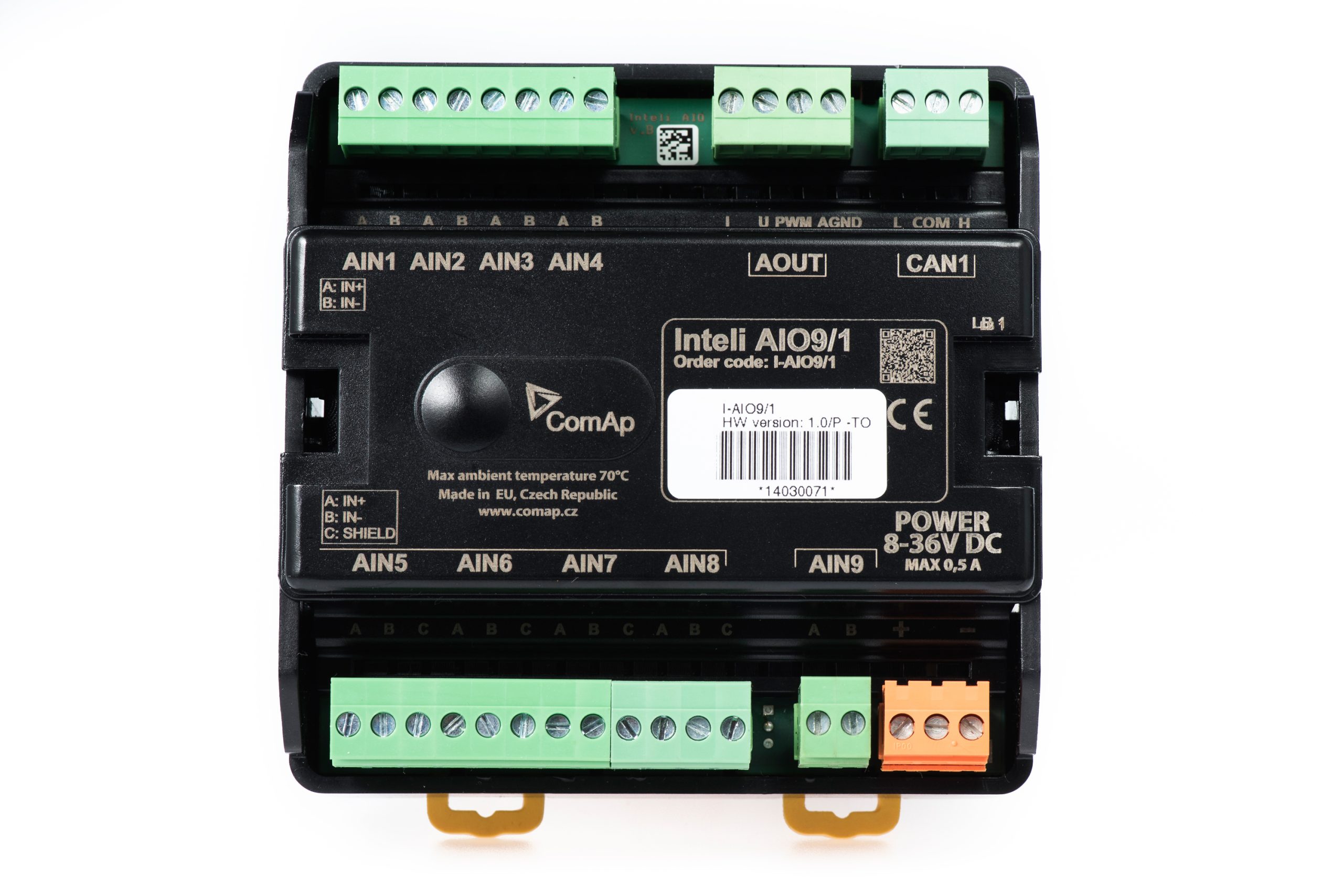

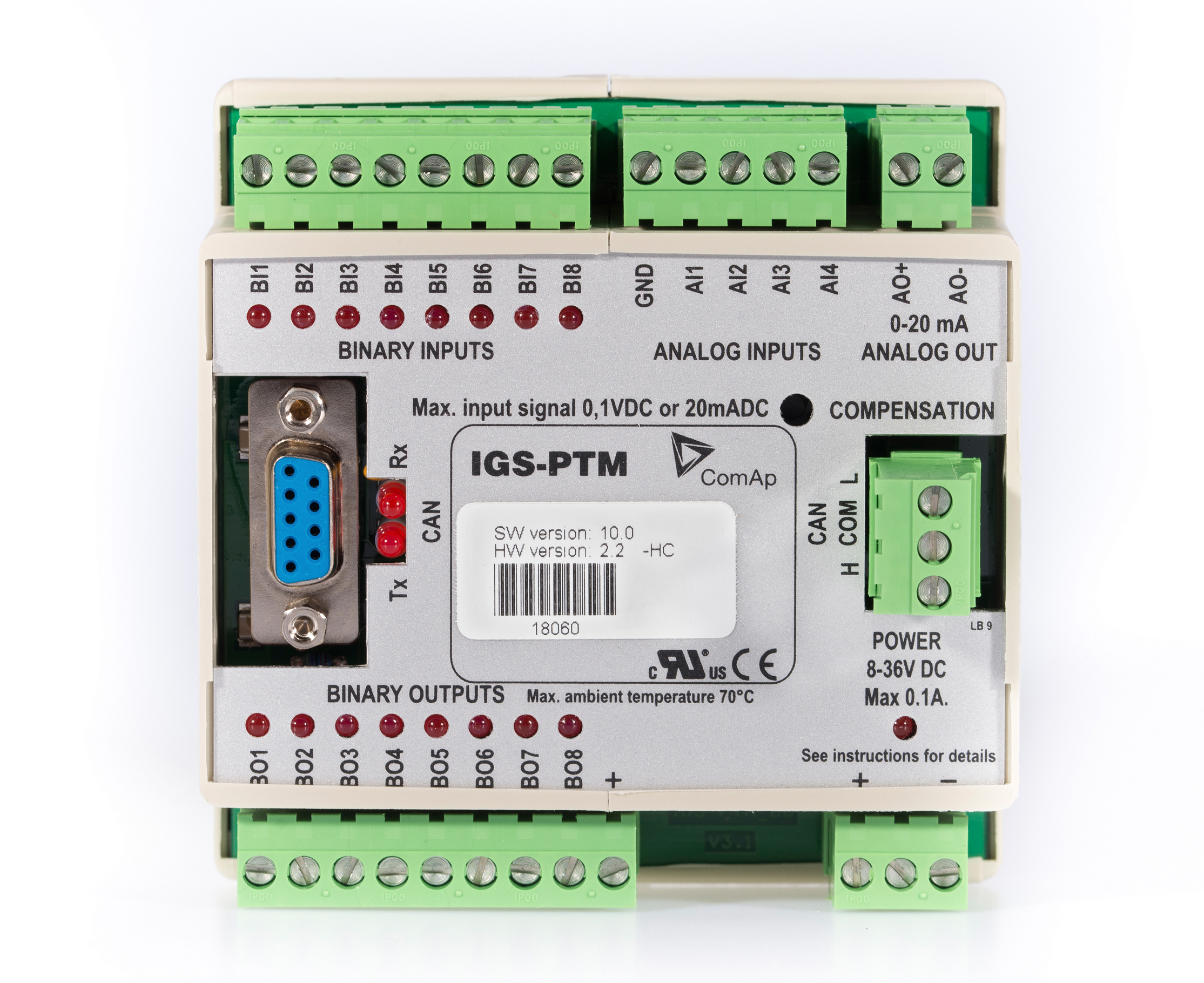

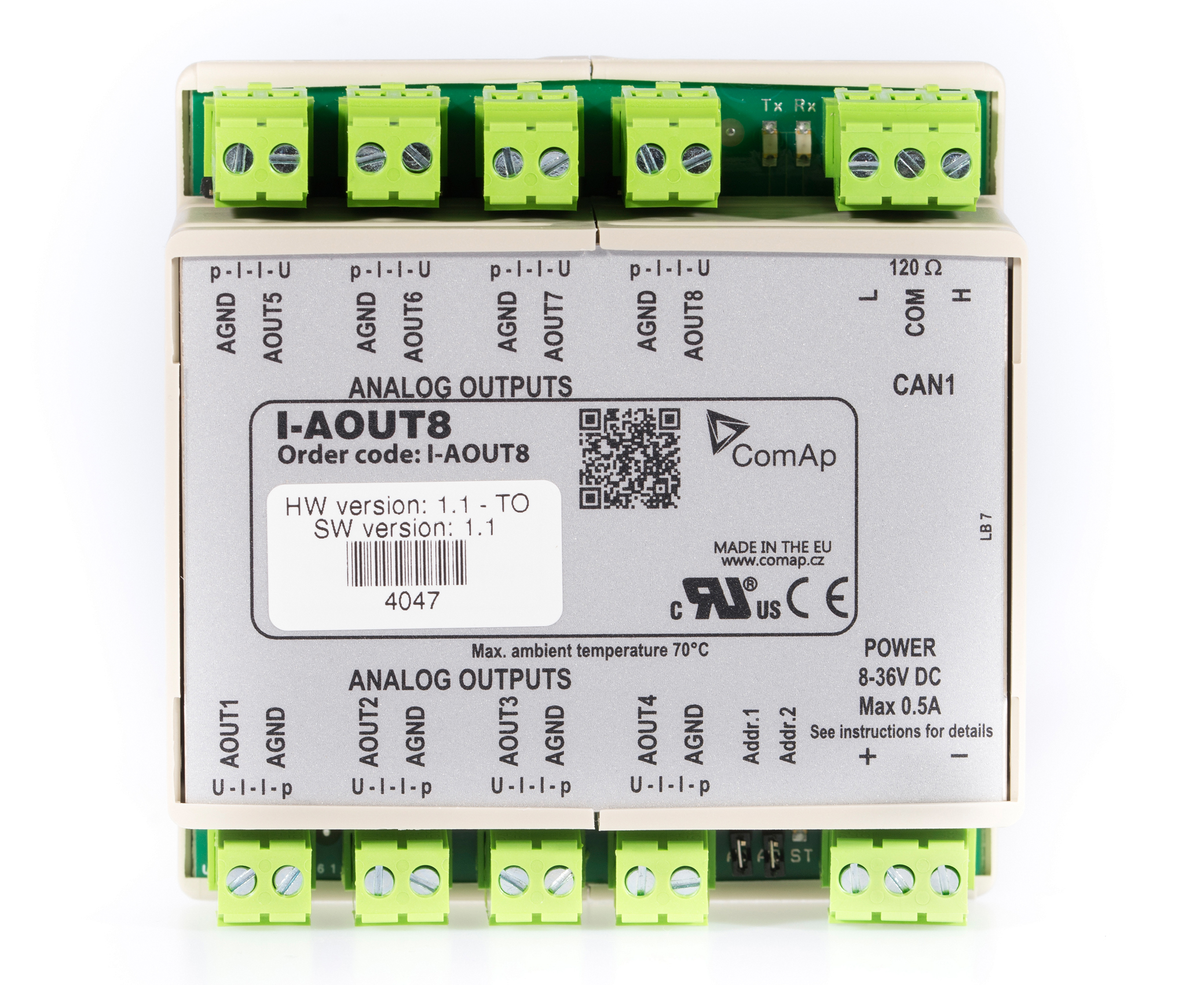

- Faster and cost-effective operations with signal sharing over a CAN bus across a group of control units

- Optional geofencing helping with efficient unit tracking and theft prevention

- Automatic Mains Failure that ensures automatic start of gen-sets and minimizes downtime

- Peak shaving for limiting the import from the mains (e.g., due to higher prices)

- Load shedding ensuring the most important loads are running even when there is a lack of power

- Controller redundancy minimizing solution downtime and ensuring the power isn’t compromised

- StageV and Tier4Final-ready by default

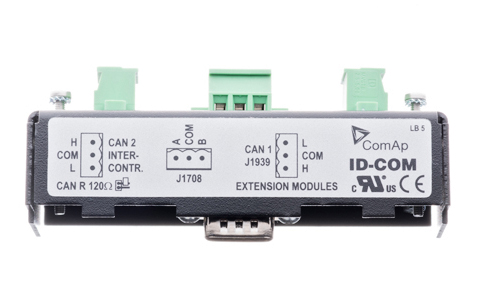

- Broad communication capabilities: USB, RS232 – RS485, Ethernet; Modbus RTU & TCP, SNMP, Internet; cellular internet connection via InternetBridge-NT module; SMS and e-mail notifications

- AirGate for easy connection to your equipment remotely, without worrying about your asset’s IP address

- Remote control and monitoring of your gen-set operations with WebSupervisor, our cloud-based fleet management tool

- Detailed data information about energy needs and gen-set fuel consumption

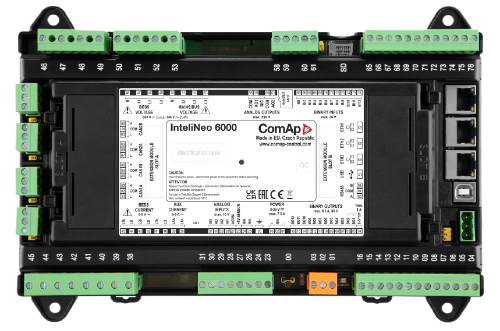

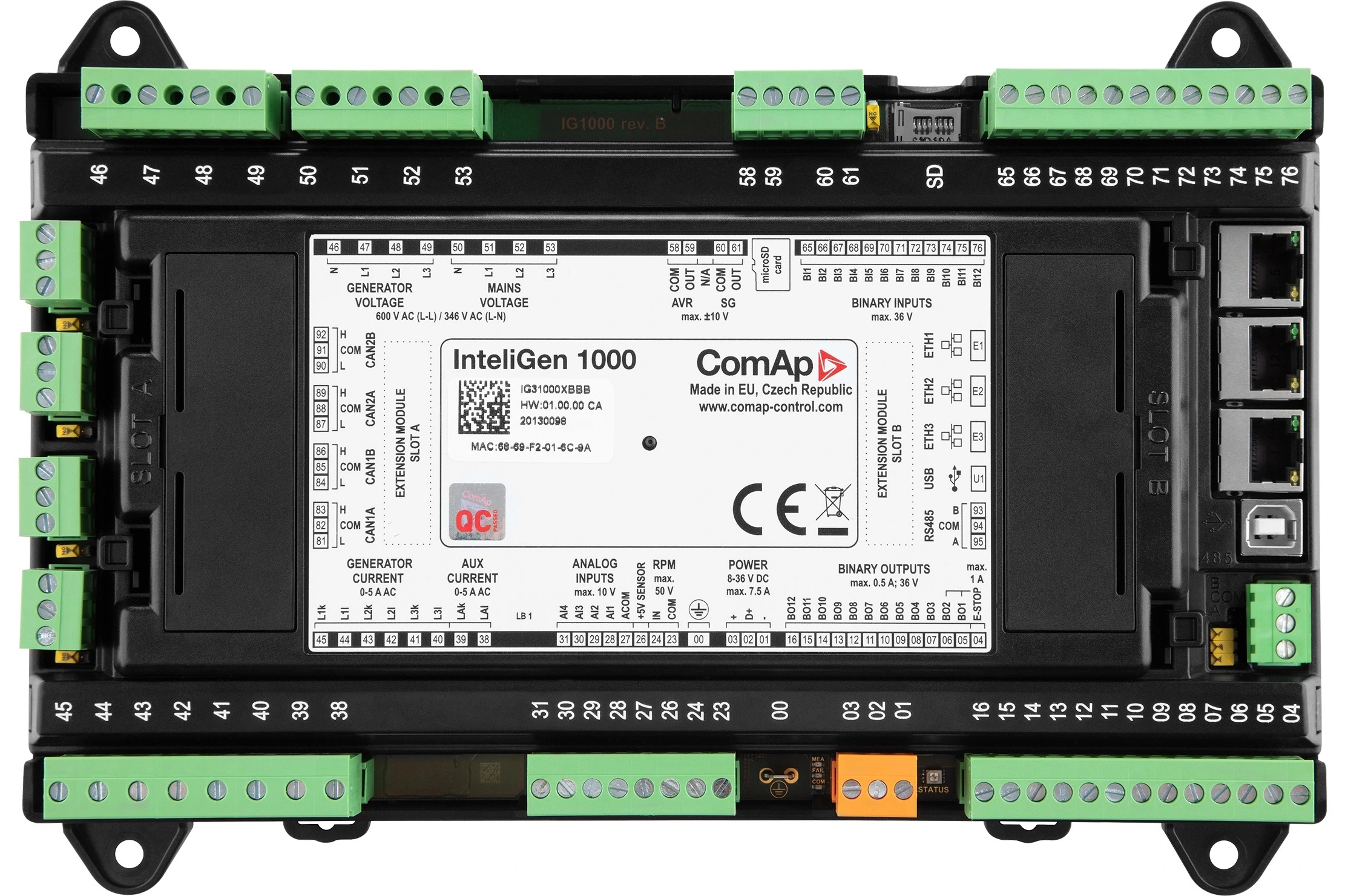

PRODUCTS

Other products